High-value Bio-oil from biomass and its applications in agriculture, water filtration, fine chemicals industry, and biofuels

In recent years, many articles have been written on renewable energies in scientific papers. Certainly, one of the best-known renewable energy is biomass. It is common knowledge that using biomass as a renewable source of energy has opened its place in the global renewable energy share charts instead of fossil fuels, and governments use biomass in various energy applications in the industry. Interestingly, biomass is not only used as an energy source in the market, but also many industrial products are biomass-based, such as agricultural products, chemical resins, adhesives, fine chemicals, water, air filters, soil amendments, and cosmetics.

Scientists have done several experiments to improve the quality and performance of biomass products since 2010. They have obtained remarkable results that promise good biomass usability in agriculture and the chemical industry in particular instead of fossil-based materials, which motivated the governments to invest more in this field.

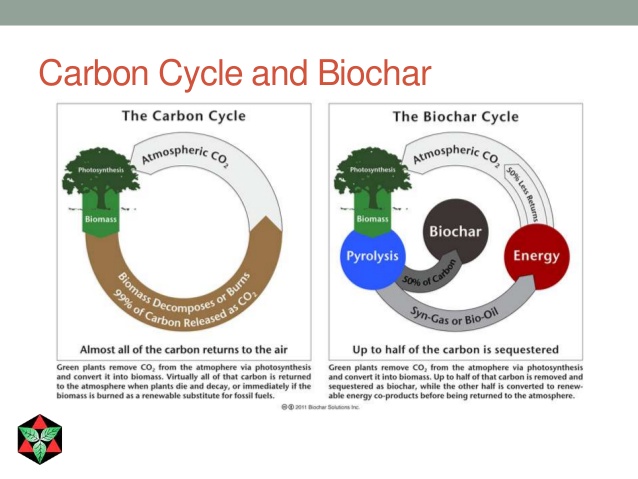

This article tries to demonstrate thermo-chemical conversion technologies technically, especially recent innovative ones called pyrolysis. Pyrolisis produces Bio-oil and Bio-char applicable in the chemical and agricultural fields. Also, some of its benefits are the reduction of environmental risks, transportation costs, and an increase in economical efficiency. This method draws scientists and industry attention in recent years for various end products. They believe in the necessity of research and development in this unique area of biomass conversion. Finally, the most unique and more applicable area of Bio-oil and Bio-char from pyrolysis described.

Biochar produced from woody weeds creates stable carbon that will last in the soil for hundreds of years with clean energy as its by-product- a method that makes more sense than wind-rowing piles of waste and burning them at night.

As I previously mentioned, biomass conversion products can be used as an energy source. This article aims to show other recent innovative applications of biomass-based products that reduce environmental risks and benefit the economy of a region. Various oxygen and hydrogen organisms exist in Bio-oil cause instability and a high tendency toward polymerization. But there is an extensive amount of chemicals with oxygen groups producing from fossil-based sources that Bio-oil can be utilized in an economical way to produce value-added chemicals.

Several experiments show that Bio-oil contains many valuable components such as phenols, aldehyde, and furan that have the potential to be used for chemical products such as Resorcinol Formaldehyde (RF) resin in particular. RF resin is an adhesive in wood structural materials that can be set at ambient temperature. A study shows that the RF adhesive resin from Bio-oil exhibited the best flexural and tensile strength. Studies show adhesive properties of Bio-oil derived from woodchips and waste paper could bond two aluminum plates with high tensile strength generally. Moreover, an investigation shows Bio-oil itself has adhesive properties and maximum tensile strength of bonding between two aluminum plates from approximately 2520 N (Bio-oil from spruce wood chips) to 2300 N (Bio-oil from waste paper)

Studies show Bio-oil from fast pyrolysis can be used for soil conditioning. The innovation here is the fact that Bio-oil reacts readily with ammonia, urea, and related compounds to form organic nitrogen. These compounds polymerize and solidify with heating to produce stable products. These compounds called slow-release fertilizers. These high-quality organic fertilizers produced from waste biomass, enhancing fast pyrolysis economic justification. The new fertilizers avoid groundwater pollution and containing the –NH2 group. So its effect could be very positive if its use and production extended to the agricultural field [6].

Providing clean water to communities is a crucial issue for many countries. Contamination including pesticides, pharmaceuticals, and a fuel compound is a growing problem, as these chemicals can cause cancer. Char filters work with the process of adsorption. For water, treatment contaminants diffuse into char pores binding to char surfaces. Large porosity and high surface area of bio-chars provide reactive ground for dissolved compounds as well as hazardous contaminants. Moreover, to avoid clog of char pores the sand pool removes a large portion of organic matter from the water.

Bio-char filters do differently from activated carbon. Most commercial activated filters are made from nonrenewable whereas Bio-char is made from biomass. Bio-char filters are not activated and they may not have the same capacity as commercial ones, that’s why their filter design may use a great amount of Bio-char.

Recent studies show Betulin extracted from fast pyrolysis of birch bark with lower cost and toxicity. These studies tried to produce activated carbon from biomass-based materials. They achieved good results by using Bio-char, a byproduct of Betulin from birch bark, which used steam or carbon dioxide as the activation agent [7].

Biochar is a carbon enriched material that can be used as soil amendments to sequester carbon and increase the physical quality of the soil such as soil structure or porosity. It also enhances water retention as well as microbial quality. Therefore, using sustainable Bio-char is an innovative and favorable practice for sustainable agriculture. Agriculture currently encountered two considerable constraints, including low-nutrient content and accelerated mineralization of soil organic matter. Field experiments show that Bio-char is much more effective than other organic matter to make nutrients available for plants and is a more stable nutrient source than manure. Also, its pore structure is hospitable to the bacteria that plants need to absorb from the soil.

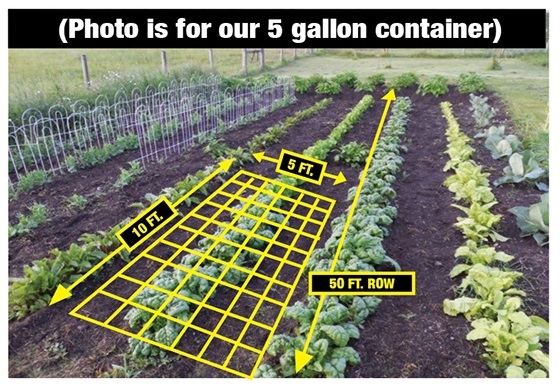

Several investigations show the effect of Bio-char on crop yields. Most studies showed that Bio-char addition increases crop yields. Therefore, Bio-char application has increased year by year since 2010, with no weak results reported.

Moreover, several experiments have been done on the evacuation of organic compounds by Bio-char. Sorption of ammonium and phosphate ions (NH4+ and PO43-) by Bio-char have been done by using the batch equilibrium method. The results show that woodchips and wood pellets start pyrolysis at 450 ̊ C to 750 ̊ C respectively, and both remove NH4+ and PO43-. Also, the Bio-char capacity for PO43- was higher than the activated carbon’s [8].

In the end, it is convincing that biomass is applicable not only in the energy sector but in the agriculture or chemical industry because it is feasible and more environmentally friendly than other fossil-based materials. Therefore, the universities, institutes, and companies should open more areas into the practical study for research and development in this field.

Studies Show that soil with up to 20% BIOCHAR are the most productive. Allowing for reduced applications of fertilizer and less frequent watering, while increasing yields by up to 50%